Acclimation is the process of delivering the wood before the scheduled installation start date and allowing it to adjust to the normal living conditions and environment inside the home.

The acclimation process starts by getting the home ready for the wood. It’s important to make sure that the project or jobsite is set up to normal living conditions. Normal living conditions will naturally occur if the thermostat settings are adjusted to the settings the residents would normally have for the same time of year when living there.

If you’re renovating a house or building a new one, it will actually be harmful to bring the wood into the home before everything is enclosed and the HVAC is fully operational. This is also the reason why wood should never be delivered and stored in the garage.

Wood is hydroscopic, which means it can take on moisture or release moisture depending on the surrounding environment. When the environmental conditions are very cold and dry, the wood will release moisture and the equilibrium moisture content (EMC) of the planks will lower. On the other hand, in the summertime when humidity levels rise, the wood will take on moisture and the EMC will rise.

When the EMC rises, the planks expand and when the EMC lowers the planks will shrink. The entire purpose of the acclimations process is to get the EMC adjusted to normal living conditions before it gets installed to minimize this expansion and contraction.

If the wood is installed prematurely, one of two things will happen:

- If the wood is installed and the moisture content is too dry for the environment, it will take on moisture after it has been installed and will swell. This could lead to potential cupping issues down the road.

- If the wood has too much moisture for the environment, it will shrink, and gaps will form between the planks.

The amount of expansion or contraction will vary depending on the dimensional stability of the species you’re having installed as well as the width of the planks. Wider planks have more surface area and it’s important to consider that wide plank floors will expand and contract substantially more than strip floors. You may consider engineered planks or rift and quartersawn cuts of wood to increase the dimensional stability. Check out this blog for more info.

So how do we know when the wood has fully acclimated and is ready for install? We use 3 very important tools to let us know when the wood is ready for installation.

- Hygrometer – will give us the relative humidity of the environment.

- Thermometer – will give us the temperature of the environment.

- Moisture Meter – will provide us with the moisture content of the planks.

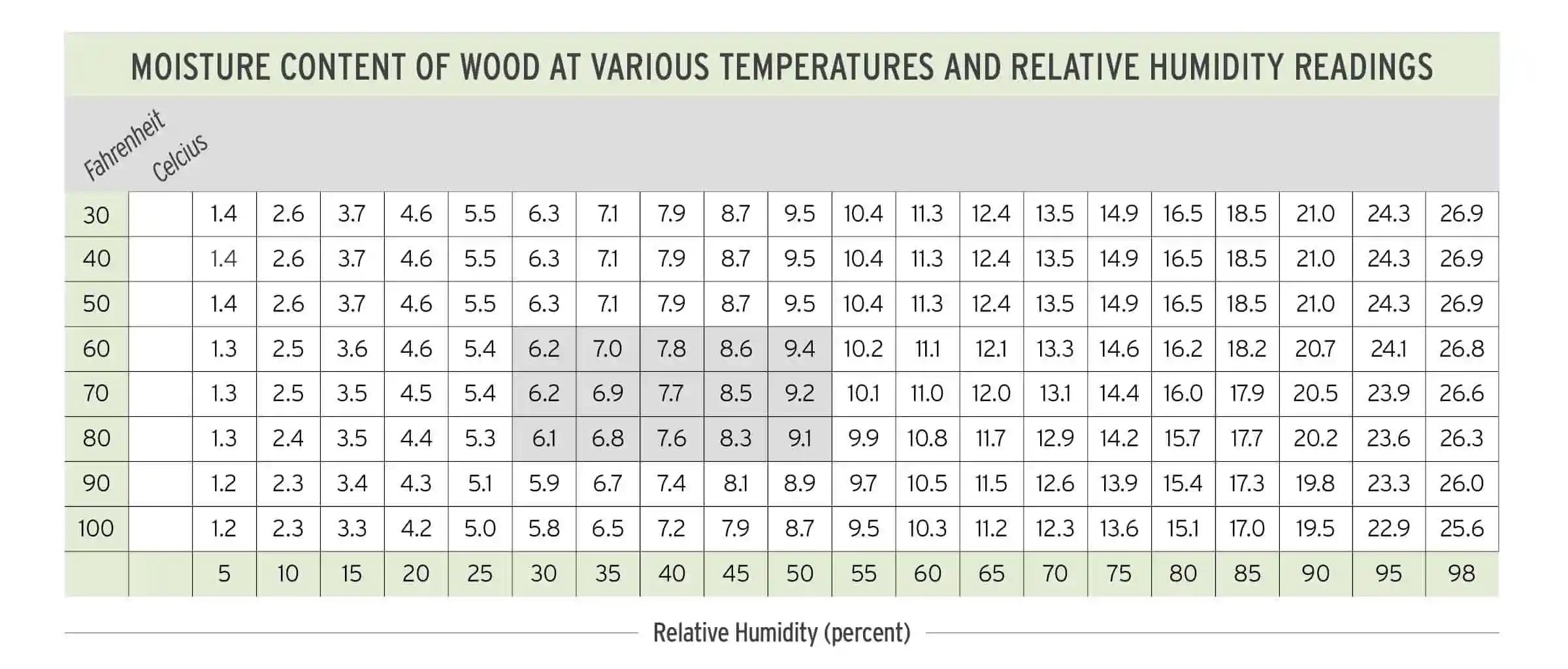

Once we have this information, we can use the chart shown above to let us know if the wood is ready for installation. We also have access to a free mobile app called Wood H2o that will tell us what the EMC should be based on the temperature and Relative Humidity.

This example from the Wood H2o app tells us the moisture content of the planks should be 7.9% whenever the temp is 70 degrees and the RH 41%.

There’s no set timetable for acclimation period, the wood may take 4 weeks to acclimate or it may be ready in 1 or 2 days. It really depends on how much of an adjustment the wood needs to make based on the environment it’s being installed in.

You’re making a significant investment by installing new hardwoods into your home, this simple step will have a dramatic impact on the performance of your floor down the road. Don’t let the contractor you hire skip out on this step. Make sure your builder or contractor has fully enclosed your home and has installed a working HVAC system before your floors are delivered.

Our Commitment To Clients

As flooring professionals, we strive to stay educated on the various flooring systems available on the market. We stay at the forefront of new advancements in the flooring industry through continued education and training courses provided by the National Wood Flooring Association. Our knowledge enables us to educate our clients on the pros and cons of various hardwood solutions. Our job is to listen to our clients and provide solutions that best fit their lifestyles. We provide easy and stress-free installations by staying informed, prioritizing clients’ needs, and setting proper expectations.